Against the industry backdrop of stricter environmental regulations, rising costs and intensifying homogeneous competition, how can coating enterprises break through the predicament?

Data from China National Coatings Industry Association shows that in 2024, the total output of China's coatings industry decreased by 1.60%, while profits increased by 9.34%. This growth was mainly driven by strong market demand for high-performance industrial coatings in sectors such as automotive, marine, 3C and photovoltaic. Additionally, some enterprises strengthened cost control, optimized and adjusted product structures, and increased the sales proportion of high-value-added products. These figures indicate that China's coatings industry is entering a period of in-depth adjustment focusing on "quality-driven" development. Focusing on high-value-added fields has become a certain growth path.

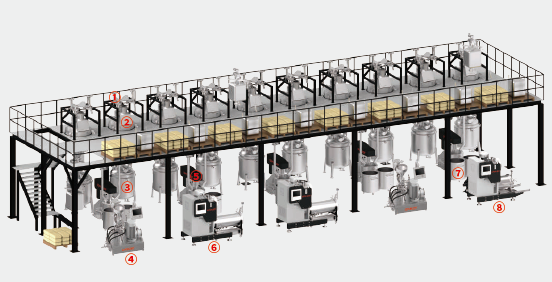

PUHLER Nano's grinding solutions directly address the core demands of efficient production and quality upgrading, helping enterprises strengthen cost control, optimize product structures and achieve profit growth in the new cycle.

01 High-Efficiency Nano Sand Mill – Low Energy Consumption, High Efficiency

30% Lower Energy Consumption, 50% Higher Capacity

Dynamic Cooling Technology Ensures Batch Consistency

Closed Design Reduces External Contamination

02 Precision Grinding Process – Guarantees Product Stability

Nano-Level Precision Control for More Uniform Particle Size Distribution

Dynamic Cooling Technology Ensures Batch Consistency

Closed Design Reduces External Contamination

03 Green Intelligent Production Line – Accelerated Transformation & Upgrading

Fully Closed Production: Over 90% Reduction in VOCs Emission

Waste Heat Recovery System Lowers Comprehensive Energy Consumption

Compliant with Latest Environmental Standards, Supporting Green Certification

Flexible Configuration to Adapt to Multi-Variety Production

Data-Driven Management Enables Intelligent Manufacturing