Liu Jie, Secretary-General of the China Coatings Industry Association, deeply analyzed industry trends at the conference: In 2025, the coatings industry will focus on supply-side reform and innovation-driven development. Functional products are expected to see significant growth. The industrial sector will maintain a medium-to-high growth rate, driven by policies for "equipment renewal." Domestic substitution in strategic fields such as electronics and new energy will accelerate, and industrial upgrading is imperative.

During the conference, Yang Fang, the Regional Sales Director of Puhler Nano's business division, delivered a keynote speech titled "The Nanogrounding Revolution." Focusing on the industry's needs for intelligent production and cost optimization in upgrading, she highlighted Puhler Nano's intelligent nanogrounding equipment and EPC engineering solutions for coatings.

Puhler Nano has been deeply involved in the coatings industry for twenty years and has always been committed to providing high-quality process equipment and intelligent solutions for the upstream and downstream of the coatings industry chain. Through intelligent automation technology, it has successfully helped many coatings companies achieve capacity upgrades and has helped customers increase the added value and profitability of their products.

Ultrasubtle Dispersing Tools for Intelligent and High-Quality Production

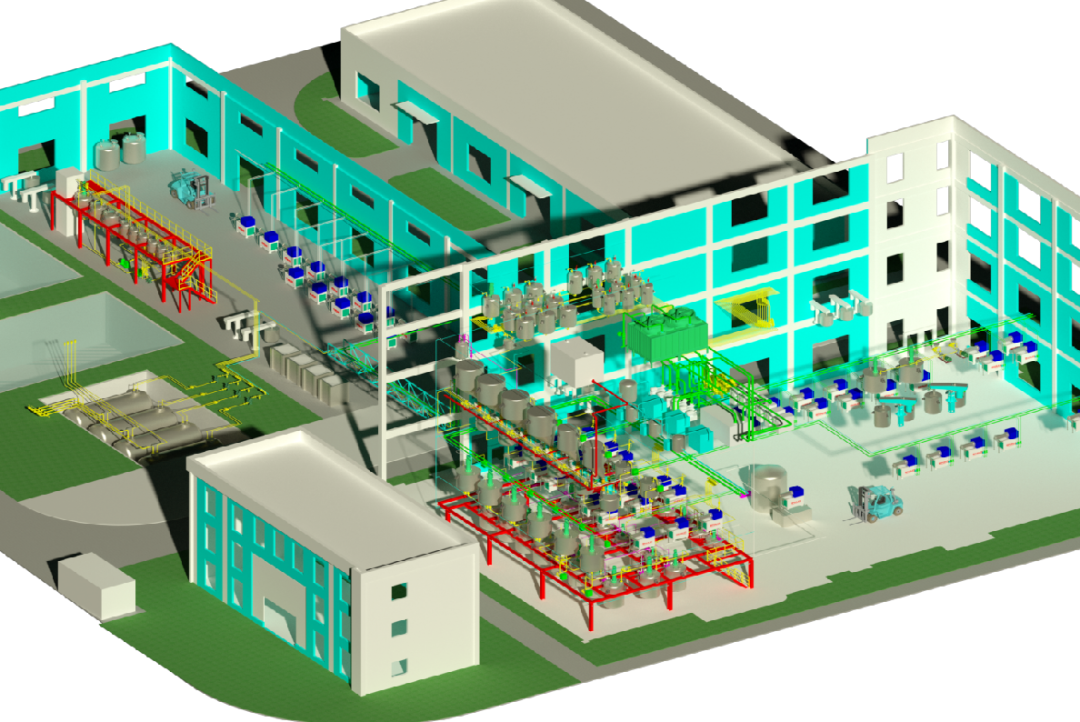

Coatings EPC Engineering: One-Stop Intelligent Manufacturing Upgrade

- Full-Process Coverage: From unpacking and feeding → raw material vacuum conveying → high-speed dispersion → multi-stage nanogrounding → color adjustment and filtration → automatic filling, the entire production line is seamlessly integrated, supporting flexible configurations from thousands to tens of thousands of tons per year.

- Flexible Production Line Adaptation: Enables rapid and accurate recipe switching to meet the production needs of various types of coatings.

- Fully Automated Production: Real-time monitoring and automatic adjustment of process parameters minimize human influence and ensure more stable performance indicators such as color, gloss, and viscosity of coatings, significantly improving product quality.

- Green Compliance: The closed production line design reduces VOC emissions, and the energy recovery system lowers overall energy consumption, helping companies meet international environmental standards such as ISO 14001.

- Data-Driven Management: Real-time monitoring of energy consumption, process parameters, and equipment health enhances fault diagnosis speed by 80% and ensures traceability of production data.

Abundant Project Cases, Reliable Technical Support