In the coating industry, "grinding" is a core link that determines product performance and quality. In 2007, when Guangzhou Puhler Machinery Equipment Co., Ltd. (now Guangdong Puhler Intelligent Nano-Technology Co., Ltd.) assembled its first experimental nano-grinding machine and basket grinder, it not only added an important part to the breakthrough of domestic coating equipment, but also marked the official start of PUHLER Group's in-depth cultivation in the field of micro-nano dispersion and grinding technology, laying a solid foundation for the company's continuous innovation and leapfrog development in the future.

01

Coating Foundation: In-depth Cultivation and

Leadership in Grinding Technology

PUHLER Group has been closely connected with the coating industry since its establishment:

Foundational Works: In 2008, guided by the concept of "branding, high-grade, and internationalization", it launched a series of products including the PHN 0.5 Lab Star nano-grinding machine, PHE horizontal grinding machine, and PBM basket grinder. These products obtained ISO9001 and EU CE certifications, quickly gained market recognition, and provided reliable equipment for coating enterprises to improve product fineness, stability, and production efficiency.

Continuous Innovation: In 2009, it launched the large-flow disc grinder; in 2010, it successfully developed the "large-flow pin-type nano-grinding machine" integrated with advanced functions such as dynamic centrifugal separator and double-end mechanical seal. This machine significantly improved grinding efficiency and product consistency, meeting the strict requirements for ultra-fine dispersion in high-end coatings and ceramic ink color glazes.

Breakthrough in Large-Scale Equipment: In 2011, it launched the 355kw super-large horizontal ultra-fine grinding machine PHE SuperMaxFlow1000. This equipment not only broke foreign technological blockade, but also solved the pain points of high productivity and ultra-fine grinding in large-scale industrial production, becoming a milestone in the industry.

This in-depth development journey in the field of coating and ink equipment has enabled PUHLER Group to accumulate profound experience in micro-nano material processing technology, forge its core capabilities in precision grinding and dispersion, and form three core underlying technologies—dry powder grinding and classification, wet slurry grinding and slurry making, and optical grinding and polishing—which constitute its solid innovation foundation. It is precisely these technological "sharp tools" tempered in the coating industry that provide strong support for its subsequent strategic transformation and diversified development.

02

Dual-Wheel Drive: Strategic Leap from "Nano Equipment"

to "Industrial Mother Machines"

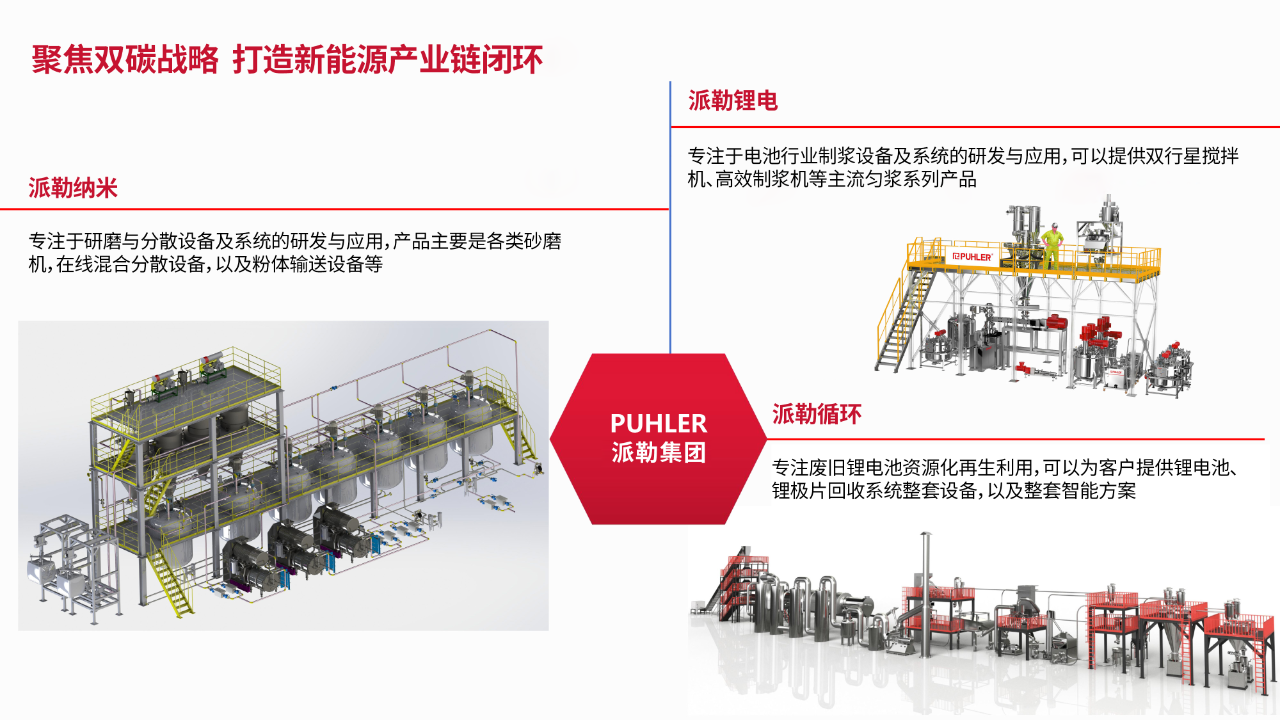

Relying on its profound accumulation in the field of micro-nano grinding technology, PUHLER Group closely follows the development pace of the country's emerging strategic industries. Especially with the rapid expansion of the new energy industry, PUHLER has technically upgraded and applied the core technology honed in serving the coating industry - the micro-nano level dispersion and grinding process - to key fields such as lithium battery cathode and anode materials, slurry and carbon nanotubes, realizing a magnificent transformation from "coating grinding intelligent manufacturing" to "new energy equipment engine".

At the same time, the strategic acquisition of Hunan Jinling Machine Tool in 2015 marked that PUHLER Group has opened up a second growth pole - "industrial mother machines" (high-end CNC machine tools). Thus, the group has built a core business pattern with "nano process equipment" and "high-end CNC machine tools" as the two wheels, and its four major industrial companies (Puhler Nano, Jinling Machine Tool, Hermann Precision Machinery, Jinling Software) work together:

03

Responding to National Policies: Forging New-Quality Productive Forces, Fulfilling the Mission of a Powerful Intelligent Manufacturing Country

Solving "bottleneck" issues: It has realized import substitution in fields such as ultra-fine grinding equipment (below 50nm), five-axis CNC systems, and large-scale mining equipment (IsaMill®), ensuring the security of the industrial chain.

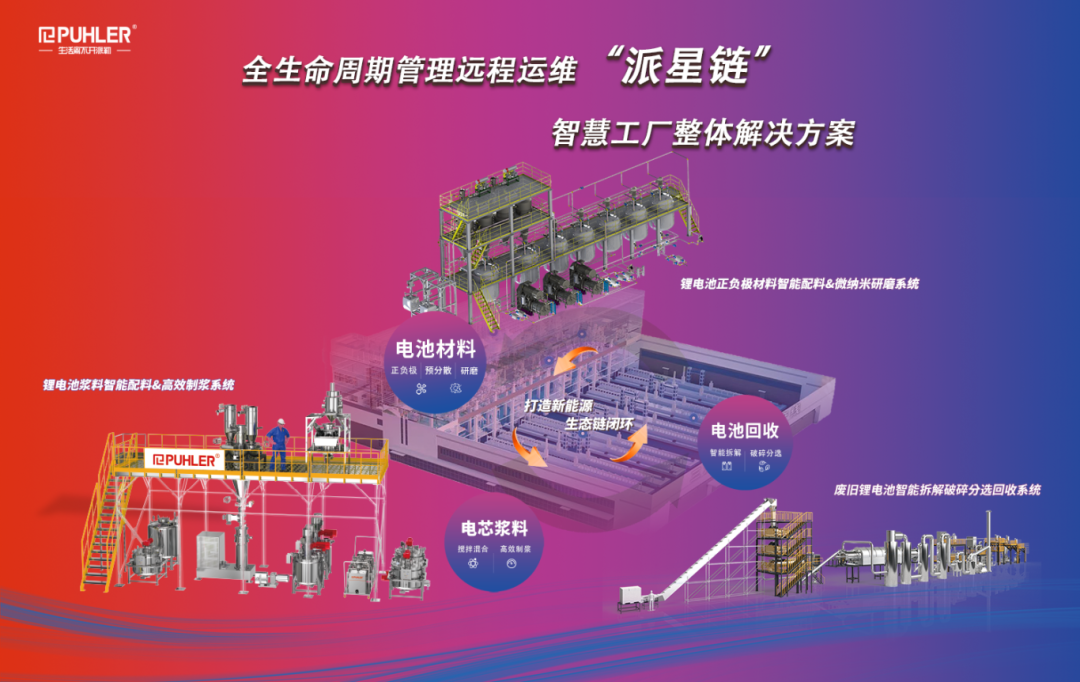

Deploying green recycling: It has created a full-chain green solution covering "battery material grinding - slurry making - recycling", and established strategic cooperation with Baili Technology to provide customers with a total smart factory solution that covers everything from equipment selection to process innovation, from hardware production to software R&D, and from construction and commissioning to operation and maintenance management services.

Empowering high-end manufacturing: Jinling Machine Tool has provided more than 60,000 sets of equipment to the world in total, and the high-end five-axis machining centers of Hermann Precision Machinery have become key equipment in fields such as aerospace.

As stated in PUHLER Group's strategy: the blueprint of "a century-old enterprise, a market value of 10 billion yuan, and an output value of 10 billion yuan" is by no means a castle in the air. Amid the dual opportunities of the new energy wave and the independent development of high-end equipment, PUHLER Group is advancing toward its global goal of becoming a world-leading solution provider of "smart factories for complete sets of micro-nano powder material equipment" and "CNC machine tools", with the craftsmanship spirit of "nano-level precision" and the responsibility of "major national equipment".

Conclusion

From the first grinding machine born in a Guangzhou laboratory to an equipment giant serving national strategic industries such as new energy, semiconductors, and aerospace, the growth code of PUHLER Group lies in deeply rooting its technological innovation gene in the soil of national development needs. When the precision of "nano equipment" meets the solidity of "industrial mother machines", the "dual-wheel drive" of this private enterprise is becoming a vivid illustration of China's breakthrough in high-end intelligent manufacturing.