Supported by the "dual carbon" goals, China has entered a peak period of energy transition. In recent years, the country has promoted the continuous expansion of the downstream new energy vehicle market through measures such as tax incentives, subsidy policies and export support. As a key force in fields such as new energy vehicles and energy storage systems, the lithium battery industry has also ushered in explosive growth. As a total solution provider for new energy materials that has been deeply engaged in key links of the new energy industry chain for many years, PUHLER has always been committed to providing the industry with cutting-edge equipment and smart services covering the entire life cycle and core links, helping customers achieve green, efficient and intelligent production goals.

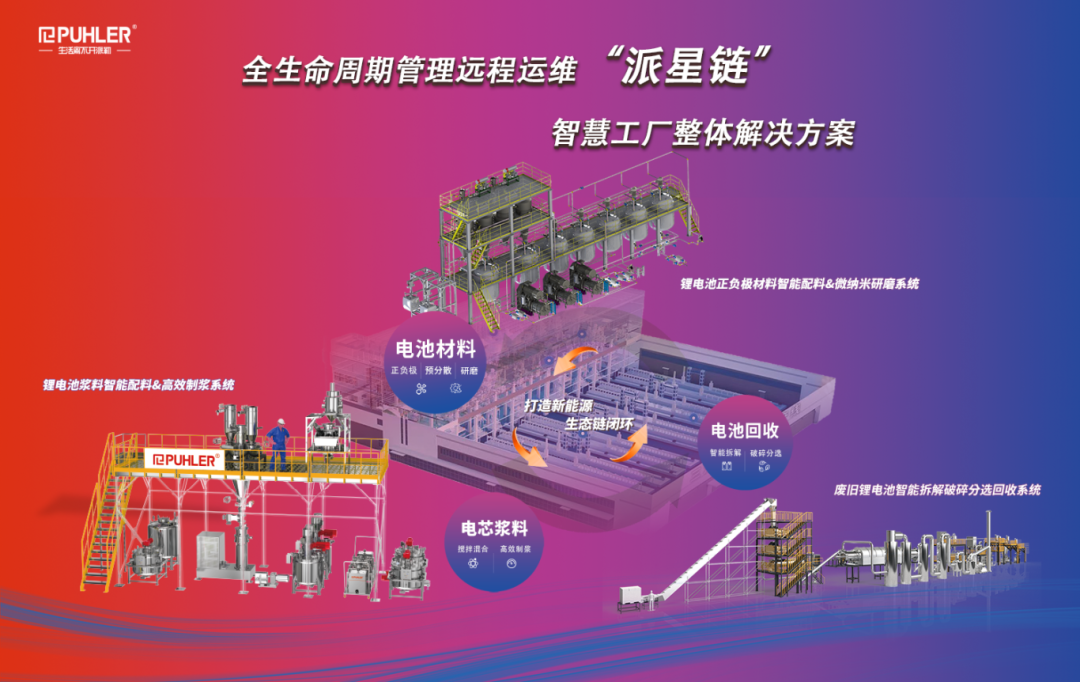

PUHLER has insight into industry dynamics and meticulously built an industry-leading full-chain green cycle system of "battery material grinding - battery slurry making - waste battery recycling". This closed-loop ecology not only focuses on the efficiency and quality of current production links, but also proactively lays out the end of the battery life cycle, promotes efficient recycling of resources, and injects strong momentum into the sustainable development of the industry.

01

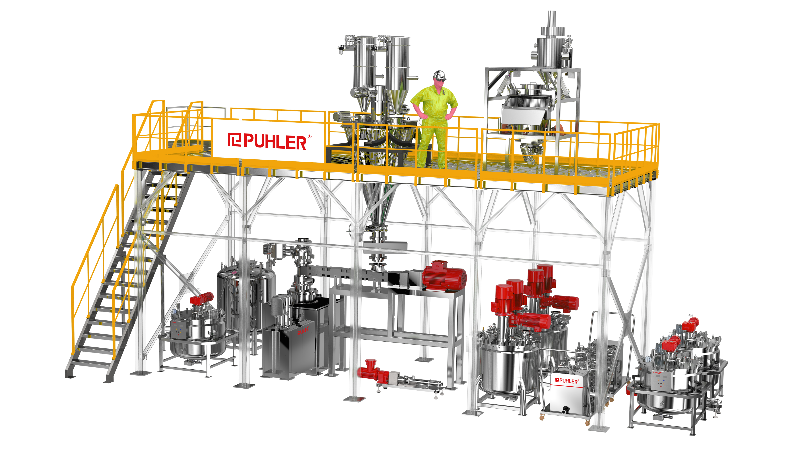

Intelligent Batching & Micro-Nano Grinding System

for Lithium Battery Cathode and Anode Materials

It adopts cutting-edge technologies such as dry grinding, dispersion grinding and single-machine double-cylinder wet grinding, providing precise, efficient and low-energy-consumption micro-nano grinding solutions for the preparation of high-performance cathode and anode materials, and laying the foundation for the excellent performance of batteries.

Main Processes

Core Equipment

02

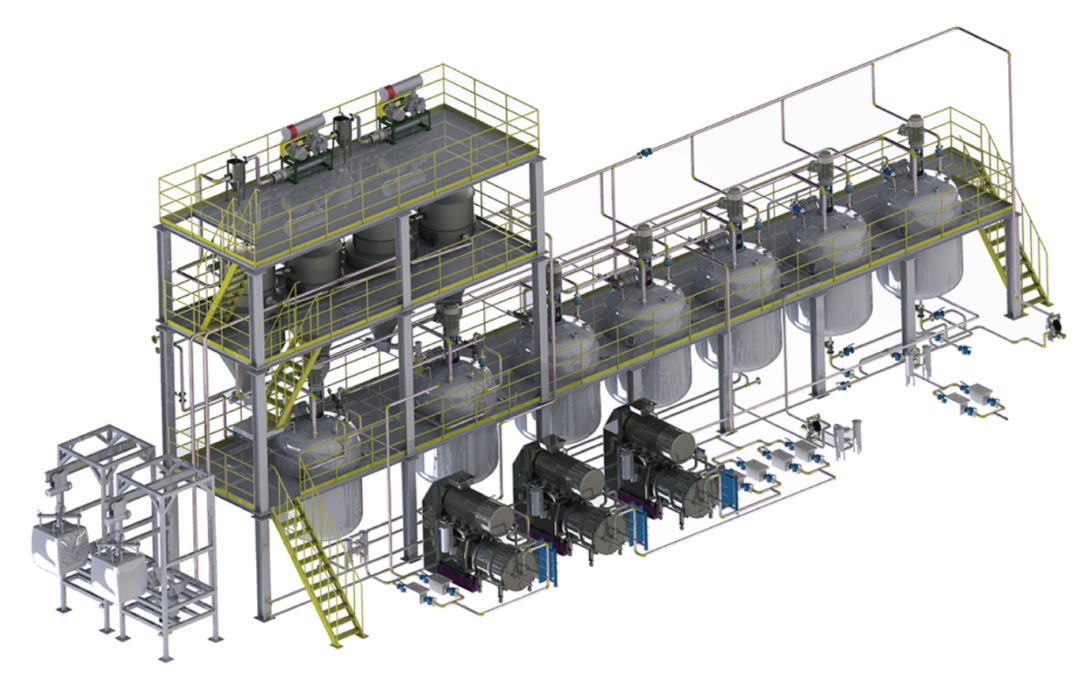

Intelligent Batching &

High-Efficiency Slurry-Making System for Lithium Battery Slurry

Centered on lithium battery slurry-making equipment, it provides an efficient, homogeneous and low-energy-consumption slurry-making system, ensuring the consistency and stability of electrode slurry, and improving battery quality and yield.

Main Processes

Core Equipment

03

Intelligent Dismantling, Crushing,

Sorting and Recycling System for Waste Lithium Batteries

Through intelligent and green recycling dismantling, crushing, sorting, and material regeneration technologies, high-value utilization of waste battery resources is realized, completing the "last mile" of green circulation.

Main Processes

04

One-Stop Smart Factory Total Solution

Understanding that customers' needs have evolved from single equipment to all-round value enhancement, PUHLER has established in-depth strategic cooperation with Baili Technology, enabling it to provide customers with a total smart factory solution that goes beyond equipment supply and covers the entire project lifecycle:

From equipment selection to process innovation: Provide the most suitable equipment combination, and based on in-depth understanding of processes, collaborate with customers for continuous optimization and innovation.

From hardware production to software R&D: Not only provide core hardware equipment with high reliability, but also integrate software systems such as intelligent control, data collection and analysis to build an intelligent production line with "integrated hardware and software".

From construction and commissioning to operation and maintenance management services: Provide comprehensive service support including professional project implementation, accurate commissioning services and efficient and reliable later operation and maintenance, ensuring the stable and efficient operation of customers' production lines and truly realizing a "turnkey" project.

After-Sales Service

"5+24" Response Service: Build a five-star after-sales service with "5-minute service response + solution provided within 24 hours" to ensure customers' equipment operates smoothly "24 hours a day, 365 days a year" and production runs without worries.

Comprehensive Database: All records from negotiation, testing, delivery, installation to maintenance are documented, providing customers with full-lifecycle services.

Long-Term Operation Support: Real-time collect equipment status through the remote monitoring platform, and abnormal data automatically triggers early warning; at the same time, provide customized training for the operation team, covering system operation logic and basic fault diagnosis, truly realizing "ready for use upon delivery and well-managed during use".

Choose PUHLER

Choose the Future

PUHLER Group is not only a reliable supplier of your new energy equipment, but also a strategic partner for you to achieve green manufacturing, intelligent upgrading and circular development. Based on our full-chain equipment strength and with the total smart factory solution as the core, we are committed to creating maximum value for customers and jointly promoting the global new energy industry towards a greener, smarter and more sustainable future.

Take action now, join hands with PUHLER to draw a new blueprint for the new energy industry!

Contact information: 13918633141