Currently, China's economic development has entered a new normal. Faced with the increasing quality demands of consumers and the expanding penetration of digital and intelligent technological innovations, structural adjustment, transformation and upgrading, and quality and efficiency improvement in the coating industry are imperative. Enhancing product quality and production efficiency is the only way for coating enterprises to move towards high-quality development.

With 20 years of in-depth engagement in the coating industry, PUHLER Nanotechnology has been committed to providing high-quality process equipment and intelligent solutions for the upper and lower reaches of the coating industry chain. Through intelligent automation technology, it has successfully helped numerous coating enterprises achieve production capacity upgrading and assisted customers in improving the added value of products and profitability.

Coating EPC Project: One-Stop Intelligent Upgrade

Full Process Coverage: From unpacking and feeding → vacuum conveying of raw materials → high-speed dispersion → multi-stage nano-grinding → color mixing and filtration → automatic filling, the whole line is seamlessly connected, supporting flexible configuration with annual output from 1,000 tons to 100,000 tons.

Flexible Production Line Adaptation: Enables fast and accurate formula switching to meet the production needs of various coatings.

Fully Automatic Production: Real-time monitors and automatically adjusts process parameters, reduces the impact of human factors, ensures more stable performance indicators of coatings such as color, gloss and viscosity, and significantly improves product quality.

Green Compliance: Closed production line design reduces VOCs emission, and heat recovery system lowers comprehensive energy consumption, helping enterprises pass environmental certifications such as ISO 14001.

Data-Driven Management: Real-time monitors energy consumption, process parameters and equipment health status, improves fault self-diagnosis response speed by 80%, and enables traceability of production data.

Core Process Flow

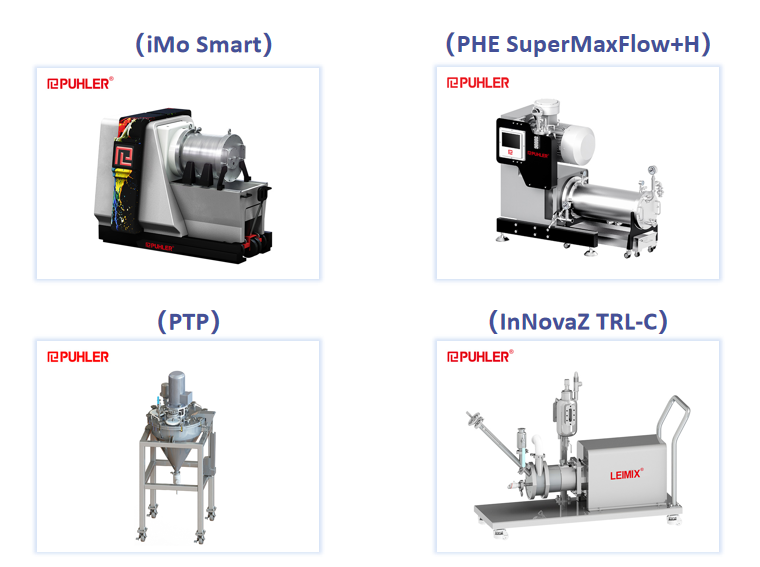

Core Equipment

PUHLER Nano Grinder adopts exclusive high-shear technology, which can accurately control micron-level and nano-level precision, meeting the ultimate requirements for gloss and stability of various metallic paints, high-gloss coatings and color pastes——

After-Sales Service

"5+24" Response Service: Build a five-star after-sales service with "5-minute service response + solution provided within 24 hours" to ensure customers' equipment operates smoothly "24 hours a day, 365 days a year" and production runs without worries.

Comprehensive Database: All records from negotiation, testing, delivery, installation to maintenance are documented, providing customers with full-lifecycle services.

Long-Term Operation Support: Real-time collect equipment status through the remote monitoring platform, and abnormal data automatically triggers early warning; at the same time, provide customized training for the operation team, covering system operation logic and basic fault diagnosis, truly realizing "ready for use upon delivery and well-managed during use".

CONTACT US

Provide Technical Support for Your Business Development

PUHLER Nanotechnology has always focused on the R&D and application of grinding technology in the material field. Relying on profound technical accumulation and rich project experience, it provides global customers with full-lifecycle support ranging from equipment selection to process innovation, from hardware production to software R&D, and from construction commissioning to operation and maintenance management services.

For more coating and ink production solutions, please feel free to contact us: 13928864454