Recently, 12 custom-made grinding machines and a set of test line equipment developed by Puhler Nanotechnology for Jiwei Chemical Paper Mill in Indonesia – a subsidiary of APP (Asia Pulp & Paper), the world's largest paper-making group – have all been successfully delivered to the project site. These delivered devices will be used by Jiwei Chemical to build a complete OMC3 thermal paper coating grinding production line, helping it achieve an efficient annual output of 6,000 tons, marking a new stage in the cooperation between the two parties!

A Decade of Collaboration

Trust with the Global Paper Giant Grows Stronger

APP's core base in Southeast Asia, undertakes the important strategic mission of radiating the Asia-Pacific market and strengthening competitiveness in the thermal paper segment. The current production line upgrade is also a key step in APP's global supply chain optimization layout.

As early as 2014, Puhler Nanotechnology entered into cooperation with Gold Huasheng Paper (Suzhou Industrial Park) Co., Ltd., a subsidiary of APP Gold Huasheng, providing a batch of equipment for thermal paper coating grinding. With stable and reliable product quality as well as high-quality and efficient services, Puhler Nanotechnology won high recognition from APP Gold Huasheng. The supply of equipment to Jiwei Chemical this time represents another upgrade of the cooperation between the two parties and also signifies that Puhler Group's products and services have gained further trust in the international market.

Customized Intelligent Manufacturing

Unlocking New Heights of Efficient Production Capacity

To meet APP's international high standards for equipment and production processes, Puhler Nanotechnology has innovatively designed a "dual-machine series process" tailored to the characteristics of OMC3 thermal paper coatings, creating a high-efficiency grinding solution:

Dual upgrading of efficiency and precision: The front-end disc sand mill achieves initial efficient dispersion and grinding of materials (from hundreds of microns to several microns); the rear-end pin-type sand mill further refines particles through a precision structure, ensuring the slurry particle size distribution and uniformity reach an ideal state. With the collaboration of the two machines, both efficiency and precision have achieved a leap forward.

Production capacity leap: 12 PHE/PHN series grinding machines (covering 6 models including PHE60 and PHN400) work seamlessly together, accurately matching the needs of each grinding stage and ensuring the stable and efficient output of 6,000 tons/year production capacity.

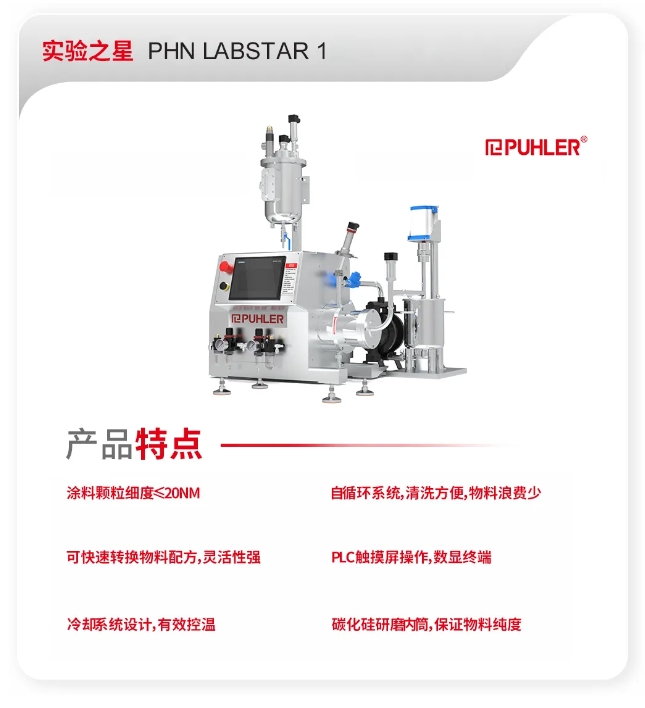

Innovation engine: The synchronously configured test line (including PHN1 experimental grinding machine, tanks, water chillers, etc.) provides an agile and efficient R&D platform, helping customers continuously optimize production processes and accelerate new product development.

Green empowerment: The core design concept focuses on low energy consumption and high stability. It not only significantly improves production efficiency but also deeply aligns with the green trend of modern industry, providing solid technical support for APP to consolidate its position as a "global benchmark for environmentally friendly paper-making".

Connecting the Globe

Empowering a New Future of Green and Intelligent Industrial Manufacturing

From Suzhou, China to Java, Indonesia, the cooperation between Puhler Nanotechnology and APP has transcended mountains and oceans, and continues to deepen. This is not only a geographical extension but also a solid cornerstone of Puhler's global journey. We sincerely appreciate the long-term trust and strategic collaboration from APP Group!

Looking ahead, Puhler Nanotechnology will continue to strive to become a world-leading provider of "smart factories for complete sets of micro-nano powder material equipment". With more efficient, greener, and smarter grinding equipment and full-cycle solutions, we will work with global partners to jointly promote high-quality development in the global paper industry as well as strategic emerging industries such as new energy and new materials, contributing "Puhler Wisdom" and "Chinese Solutions" to building a sustainable global value chain!