On May 17th, the highly anticipated 17th Shenzhen International Battery Technology Exchange/Exhibition (CIBF2025) came to a successful conclusion. At this exhibition, Puhler made a brilliant appearance with a variety of core preparation equipment for new energy materials and overall smart factory solutions, comprehensively demonstrating the company's core strength in the R&D of new energy material intelligent manufacturing technology, scenario-based applications, and industry ecosystem construction, which attracted enthusiastic attention from global professionals.

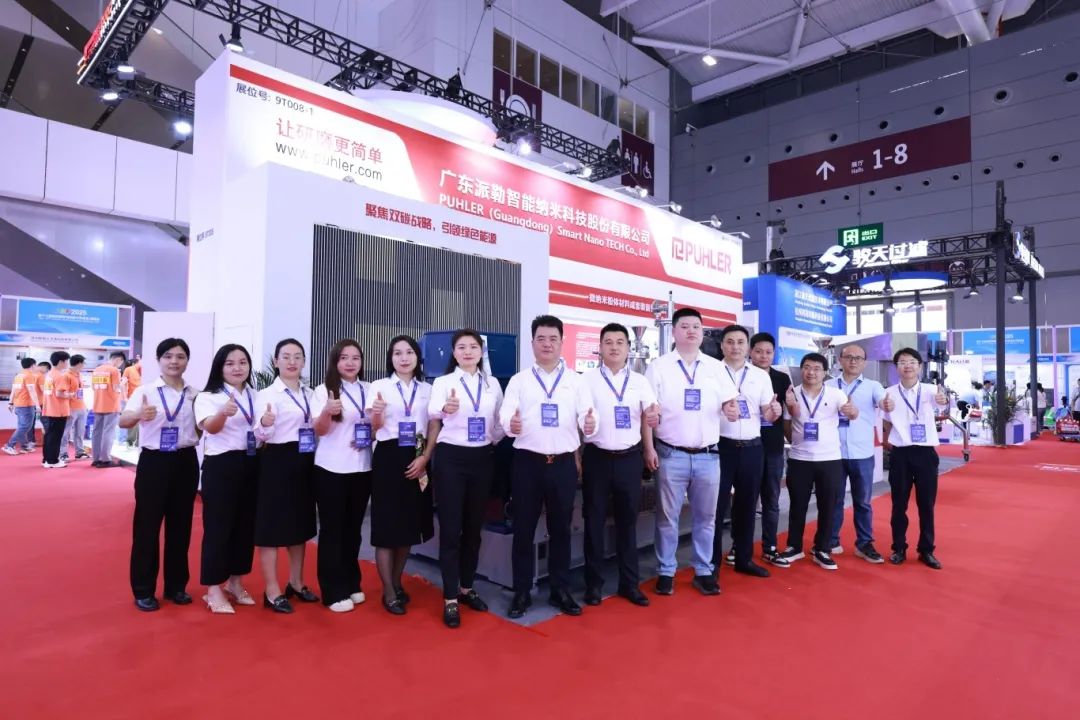

During the three-day exhibition, Puhler's booth welcomed numerous international exhibitors, procurement teams from domestic leading enterprises, and technical leaders. The on-site communication atmosphere was strong, with a total of over 3,000 customer visits received!

Strengthening and Complementing the Industrial Chain

Jointly Building a New Energy Intelligent Manufacturing Ecosystem

At this grand gathering of the battery industry, Puhler innovatively released the strategic system of "Full-Scenario New Energy Intelligent Manufacturing Ecosystem Matrix". This strategy is committed to building a world-class high-end equipment manufacturing and technology service enterprise with global competitiveness, and becoming a world-leading provider of overall solutions for smart factories in new energy and new materials.

At present, Puhler has formed a closed-loop green and low-carbon circular ecosystem industry chain covering "new energy material grinding - lithium battery dispersion and pulping - battery disassembly and recycling", helping customers achieve diversified development of new energy application scenarios.

In addition, to strengthen the resilience of the industrial chain, Puhler Group successfully joined hands with Baili Technology in 2024, and reached a strategic cooperation with its subsidiary Baili Lithium this year. Through technical collaboration and resource integration, efforts have been made to strengthen and complement the industrial chain, thus establishing a smart factory EPC general contracting service system that covers everything from equipment selection to process innovation, from hardware production to software R&D, and from construction commissioning to operation and maintenance management services. This system provides customers with value-added solutions throughout the entire life cycle.

Hardcore Product Matrix

Defining a New Industry Height

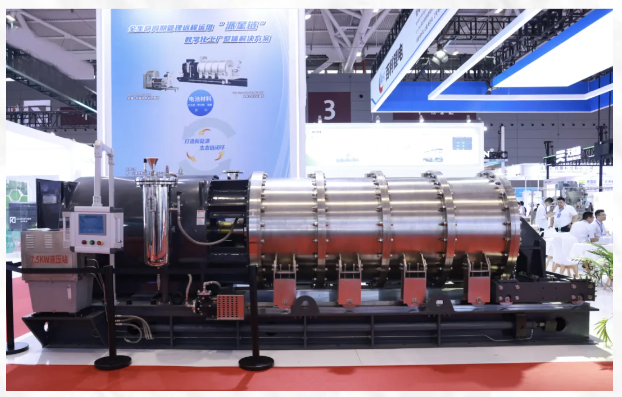

It is worth noting that all the intelligent equipment exhibited by Puhler this time, including laboratory sand mills, laboratory high-efficiency pulping machines, lithium battery dismantling and recycling systems, dry grinding systems, and extra-large horizontal/vertical pin-type nano sand mills, have been newly upgraded with AI interaction functions. Their production line systems can intelligently establish and store proprietary knowledge bases, enabling language-interactive process consulting and intelligent experiment assistance, etc. This can effectively reduce customers' trial-and-error costs, shorten the cycle of customers' new construction and expansion projects, and provide guarantees for customers' new capacity construction and expansion.

Bustling Booth

Global Merchants Co-Drafting a Blueprint for Cooperation

During the exhibition, Puhler's booth received an average of over 1,000 visitors per day, with domestic and foreign purchasers flocking in.

From product features to multi-field applications, from technological breakthroughs to market trends, and from domestic client communications to overseas exchanges, every conversation was like a "technical collision". It fully demonstrated the company's comprehensive strength and application advantages in the battery raw material manufacturing equipment system, covering everything from experimental research and development to large-scale mass production, and from traditional processes to advanced technologies.

At the exhibition site, Puhler's team communicated and negotiated with visiting customers with professional capabilities and enthusiastic attitudes. They carefully answered questions and conducted all-round discussions on Puhler's brand, product applications, product advantages, and after-sales services. We not only gained cooperation intentions but also heard the real feedback from customers on their future needs。

The curtain falls but the journey continues

we forge ahead with determination

"Linking the Globe · Empowering Green · Driving the Future" – with this, CIBF2025 has successfully concluded. We would like to express our gratitude to every guest for their presence and support for Puhler!

In the future, Puhler will continue to focus on the country's "Dual Carbon Strategy", actively practice ESG concepts, and uphold the philosophy of professionalism and innovation. We will keep providing high-quality overall smart factory solutions and intelligent operation and maintenance services for the new materials, new energy, and traditional energy industries, jointly promoting the prosperity and development of the new energy sector.

The curtain falls but the journey never ends; we forge ahead with unwavering resolve! After 24 years of unceasing progress, we once again thank everyone for their visit. Let's renew our appointment for new energy intelligent manufacturing!