On May 15th, the highly anticipated 17th Shenzhen International Battery Technology Exchange/Exhibition (CIBF2025) grandly opened at the Shenzhen World Exhibition & Convention Center. As a landmark event in the global new energy sector, this exhibition has gathered well-known enterprises from various countries, dedicated to promoting the high-quality development of the new energy industry.

Puhler Group continues to focus on national strategic needs and actively practices the concept of ESG development. At this exhibition, Puhler made a grand appearance with its new energy core equipment matrix and innovative system solutions, competing alongside more than 3,000 renowned enterprises worldwide and jointly celebrating this industry event.

A Gathering of Merchants, A Collision of Technologies

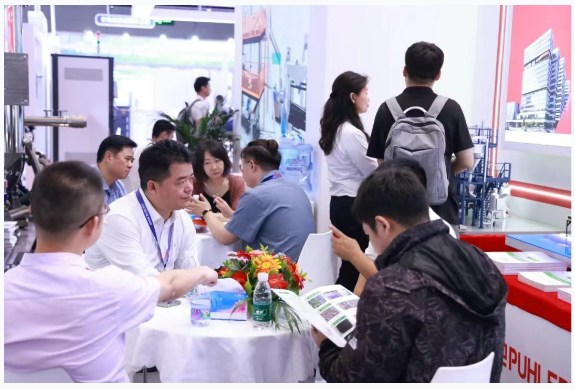

Puhler has long been integrating the sustainable development strategy deeply into product R&D and market expansion. On the opening day, Puhler's booth, relying on green and low-carbon innovative technologies and superior product performance, attracted numerous industry experts and enterprise customers from home and abroad to visit and experience, with a continuous stream of on-site consultations and negotiations.

The company's team introduced in detail the product performance, advantages, application fields and case analyses to each customer, intuitively demonstrating Puhler's technical strength and market competitiveness in the new energy sector.

Top-Tier Products, Leading with Strength

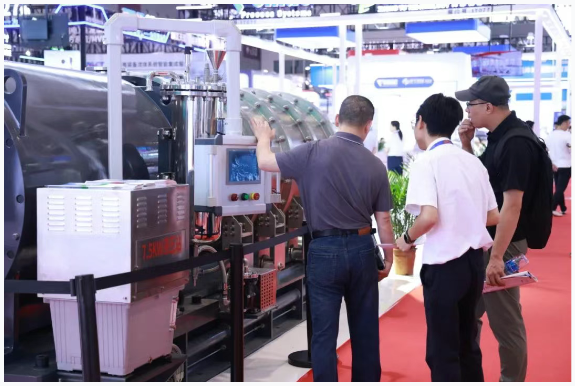

At this exhibition, Puhler focused on the core needs of the industry and showcased a range of core equipment, including the PHN 1500 Pin-type Nano Grinder, KDP400H Glory·Dual-Drive Nano Grinder, KDP0.5 Lab Star, PHK15 Vertical Nano Grinder, HHGN 100 High-Efficiency Pulping Machine, and intelligent disassembly production line for waste lithium batteries. These devices provide efficient support for key process links such as lithium battery cathodes and anodes, sodium-ion battery materials, conductive pastes, and overall battery homogenization solutions.

Meanwhile, Puhler also exhibited system solutions covering core process links such as pneumatic conveying, dispersion and grinding, and automatic feeding and batching. Ranging from single-machine equipment to one-stop intelligent production line solutions, Puhler helps customers achieve cost reduction, efficiency improvement, and large-scale production.

Strong Alliances, Shining in the Industry

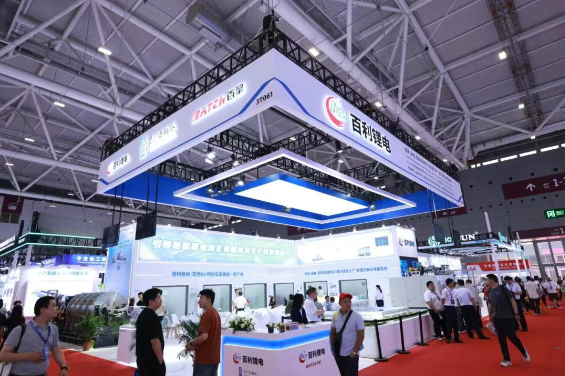

It is worth mentioning that at this exhibition, Puhler and Baili Lithium joined forces to present an industry benchmark case. The PHN1500 pin-type nano grinder jointly exhibited by the two parties in the core area of Baili Lithium's booth (3T061) became the focus of attention, thanks to Puhler's original cutting-edge grinding technology, high-reliability design and excellent system compatibility advantages.

This collaboration not only demonstrates Puhler's technological leadership in the new energy equipment sector but also pioneers an ecological cooperation model of "specialized, sophisticated, distinctive, and novel equipment suppliers + whole-line solution service providers". Through two-way empowerment between cutting-edge exploration in equipment R&D and scenario implementation in production line integration, both parties will provide more intensive and intelligent Industry 4.0 solutions for the lithium battery industry, helping global new energy enterprises achieve cost reduction and efficiency improvement throughout the entire life cycle.

As a leading provider of new energy equipment solutions in the industry, Puhler has always been committed to promoting the development of green energy and providing more efficient and reliable products and services to global customers.

Up to now, Puhler has provided nano-grinding solutions for more than 50 new energy leading enterprises such as CATL, BYD, Gotion High-tech, and Guizhou Linhua Phosphorus Chemicals. It has also established a standardized production line solution library covering the entire lithium battery material system including lithium iron phosphate, ternary materials, and silicon-carbon anodes. Its products and services have spread to more than 100 countries and regions around the world.