A high-quality numerical control (NC) system has significant multidimensional impacts on the machining performance of the same machine tool, specifically reflected in key technical indicators such as machining accuracy, processing efficiency, machining stability, capability to handle processing complexity, and the intelligentization level of the machine tool. Since Jinling Machine Tool officially launched the DELTA WHM 632i Ultra V2 five-axis simultaneous machining center NC system in March 2024, the system has rapidly attracted high attention from industry users and numerous active inquiries from potential users by virtue of its technological innovation and market adaptability.

Real Combat Reveals the Truth: Live Production Data

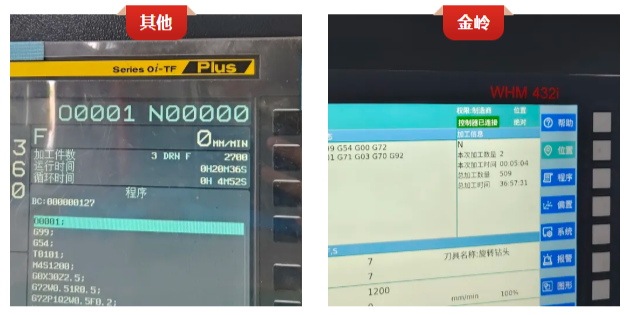

Recently, to more intuitively verify the capabilities of this independently developed numerical control (NC) system, Jinling Machine Tool conducted a "real-world combat drill" in its workshop. The company used two machines to process the same batch of metal connectors (made of #45 steel): one equipped with a numerical control system from another brand, and the other with Jinling's self-developed NC system—the CKT200 inclined bed CNC lathe.

Actual production comparisons show that the inclined bed lathe equipped with Jinling's numerical control software can control machining accuracy errors within ±0.005mm, reaching the micrometer level. Overall, although the processing time is slightly shorter than that of international brands, its performance in machining accuracy is not inferior, and the surface smoothness of the workpieces is comparable.

In comparison with other renowned numerical control systems, the advantage of Jinling's self-developed NC system lies in its stronger openness and adaptability. It can be compatible with motors from more brands, providing customers with more flexible choices.

So far, after multiple rounds of technical verification, Jinling's entire system has achieved technological self-control of key components, including motion controllers, motion control algorithms, human-machine interaction software, and numerical control panels, with the self-control rate of core components exceeding 85%.

In addition, the system has been maturely applied in multiple products such as CKT series three-axis CNC lathes and five-axis simultaneous machining centers, completed the development of the lathe system, and can adapt to the advanced production needs of multiple series products under Jinling Machine Tool.