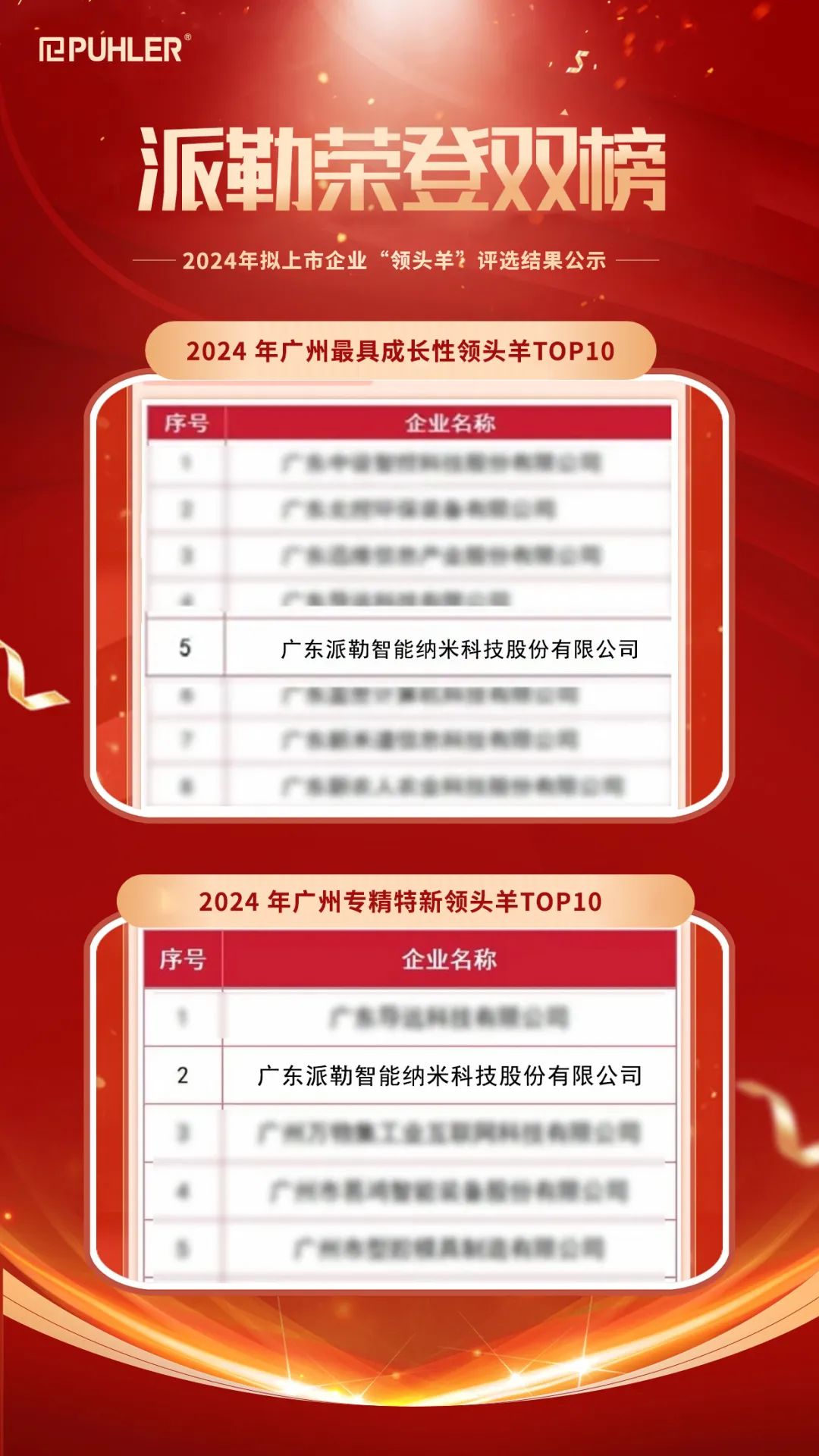

Recently, at the “Guangzhou Capital Market Empowerment of Modern Industrial System Construction and Leading Sheep Selection Summary Conference” hosted by the Guangzhou Financial Development Service Center, Guangdong PUHLER Intelligent Nanotechnology Co., Ltd. (hereinafter referred to as “PUHLER Nano”), a subsidiary of PUHLER Group, won two major awards: “Top 10 Most Growth Potential Leading Sheep in Guangzhou in 2024” and “Top 10 Specialized, Refined, Unique, and Innovative Leading Sheep in Guangzhou in 2024” for its outstanding comprehensive strength. This is not only a high recognition of PUHLER Group's industry leadership but also a full affirmation of the group's overall development strategy, technological strength, and capital potential.

Aligning with National Policies: Diversifying Industrial Layout

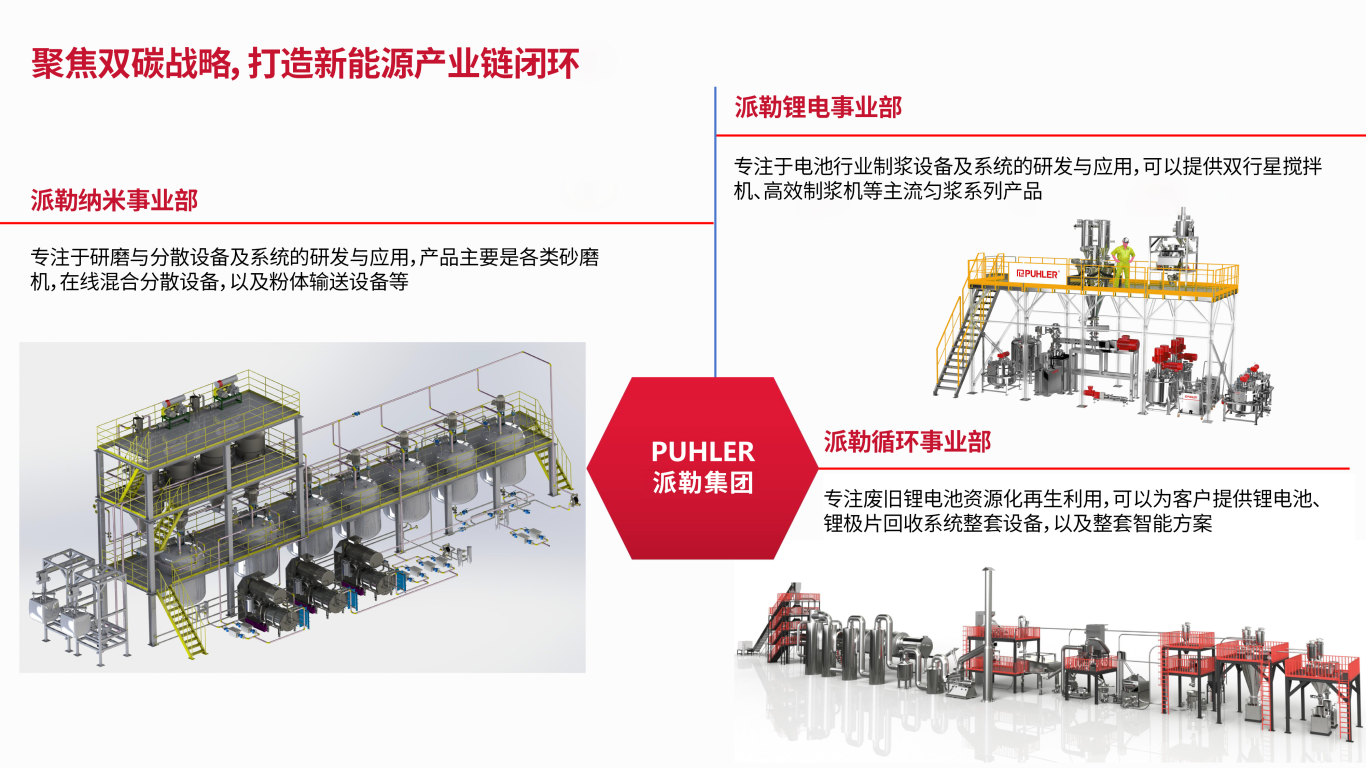

Since its inception, Puhler Group has keenly grasped the pulse of national strategy and closely aligned with the strategy of becoming a manufacturing powerhouse. Under the backdrop of implementing the “dual carbon” strategy and advancing high-end manufacturing, the group has actively integrated into the wave of new productive forces and diversified its industrial layout. Its four core industrial companies—Guangdong Puhler Intelligent Nanotechnology Co., Ltd., Hunan Jinling Machine Tool Technology Group Co., Ltd., Hermann Precision Machine Tool (Guangdong) Co., Ltd., and Changsha Jinling Software Technology Co., Ltd.—each excel in their respective niche fields such as micro-nano grinding processes, new energy intelligent manufacturing, and high-end CNC machine tool manufacturing, jointly driving industrial upgrading.

Relying on three core underlying technologies—dry grinding and classification of powders, wet grinding and slurry making of pastes, and optical grinding and polishing—the Group has established a core product system covering five major areas: micro-nano grinding equipment, lithium battery slurry making equipment, intelligent recycling production equipment for power batteries, CNC machine tools, and CNC systems. Meanwhile, leveraging its rich project experience and professional technical strengths, the Group provides one-stop EPC engineering digital solutions for customers in industries such as aerospace, new energy, and semiconductors. These solutions meet the modern manufacturing industry's needs for digitalization, intelligence, greenness, and cost reduction, and help industries move towards high-end development, fully demonstrating the characteristics of a "specialized, refined, unique, and innovative" enterprise.

Breakthrough in Technology: Leading Industry Innovation

Technological innovation is the core engine driving the development of Puhler Group and the key force in breaking through the dilemma of "bottleneck technologies" to achieve domestic substitution. Relying on its profound technical strength, the group has accumulated over 200 authorized patents with a self-sufficiency rate of core technologies exceeding 85%, thus building a robust technological barrier.

In the field of micro-nano grinding processes, the company has mastered the key core technology of achieving a wet grinding fineness of less than 50 nanometers for solid particles using physicochemical methods. It has become the first enterprise in China to realize mass production of a 5,000-liter capacity grinder with a fineness of 50 nanometers. In the field of lithium battery slurry making, the company's "TWIN SHIFT" series of topological helical twin-rotor intelligent slurry making systems have realized the domestication of fully automated lithium battery manufacturing equipment technology, with performance surpassing that of imported products. In the field of power battery recycling, the company's independently developed integrated process technology and equipment for recycling waste batteries—featuring "electrified crushing, low-temperature pyrolysis, coupled separation, and material regeneration"—is a significant innovation both domestically and internationally, leading the global industry. This technology provides crucial support for resource recycling under the dual carbon strategy.

In the field of CNC machine tools and numerical control systems, the company's independently developed HGC and HUC series of high-end five-axis linkage CNC machining centers have achieved comprehensive domestication in terms of machine design, machining accuracy, key components, and control systems, with an autonomy rate exceeding 85%. The DELTA WHM 632i Ultra V2 five-axis linkage machining center control system has realized a breakthrough in sub-nanometer level precision motion control, endowing China's high-end equipment with an "intelligent brain" and overcoming the long-standing "bottleneck" challenges that have constrained industry development.

Capital Support Accelerates Rapid Development and Soaring Growth

The favor of capital is a strong proof of a company's development potential. At present, the shareholders of Puhler Group include state-owned venture capital platforms such as Guangdong Science and Technology Venture Capital, Suikai Investment, Hunan Investment Group, and Guangzhou Industry Investment, as well as other private equity funds. The support from leading capital and industrial investors has injected strong momentum into the development of Puhler Group, helping the company to accelerate its development in the layout of capital and industrial resources.

The coronation as a double "leading sheep" is both a milestone and a new starting point. Moving forward, Puhler Group will fully leverage the resources of Guangzhou's "Leading Sheep" action plan to steadily advance the company's listing process. By utilizing the advantages and resource optimization functions of the capital market, the group will push forward with its "Three Hundred Strategy" blueprint of becoming a "century-old enterprise, with a hundred billion market value and a hundred billion output value." It will steadily move towards the goal of becoming a world-leading provider of "intelligent factories for complete sets of micro-nano powder material equipment" and "CNC machine tool" solutions, contributing more to industry development and the implementation of national strategies.