According to the latest data, the global solid-state battery market has already broken through the trillion-yuan mark in 2025! This rising star in technology is illuminating the future of new energy at an unprecedented speed and is beginning to stride into a golden age!

According to the prediction of the China EV 100 Forum, all-solid-state batteries will start to be installed in vehicles by 2027 and are expected to achieve mass production by 2030. Many automakers have also announced their timelines for the mass production of solid-state batteries. For example, BYD plans to begin mass demonstration installation of all-solid-state batteries around 2027. Changan Automobile announced that it will launch the first functional prototype vehicle with solid-state batteries in 2025 and gradually mass-produce all-solid-state batteries by 2027. In addition, companies such as Toyota, Contemporary Amperex Technology Co. Limited (CATL), and Guoxuan High-Tech are actively laying out research and development and mass production of solid-state batteries.

Solid-state batteries, with their high energy density, ultra-long life, and intrinsic safety, are disrupting the fields of power batteries, consumer electronics, and energy storage. However, large-scale application of solid-state batteries still faces many challenges, among which material preparation processes are a key link.

Solid-State Battery Material Technology Focus:

Nanosizing and Process Refinement

The core breakthrough of solid-state batteries lies in the compatibility of solid electrolytes (sulfides/oxides/polymers) with high-nickel cathodes and lithium metal anodes. To enhance ionic conductivity and reduce interfacial impedance, the particle size of the materials generally needs to be controlled within the range of 50–200 nanometers (according to laboratory data from Toyota Research Institute in Japan, when the particle size of lithium sulfide is controlled below 50 nanometers, the ionic conductivity can even be increased by two orders of magnitude), and the uniformity of particle size distribution must be achieved (PDI < 0.1). However, traditional grinding equipment commonly suffers from low efficiency (single grinding > 8 hours), uneven particle size (D90 deviation > 15%), and high risks of metal contamination, which severely restrict the yield and cost control of mass production.

Against this backdrop, PUHLER Nanomill, with its unique advantages, provides an effective solution to address these technical pain points.

01

Nanometer-Level Precision Breakthrough

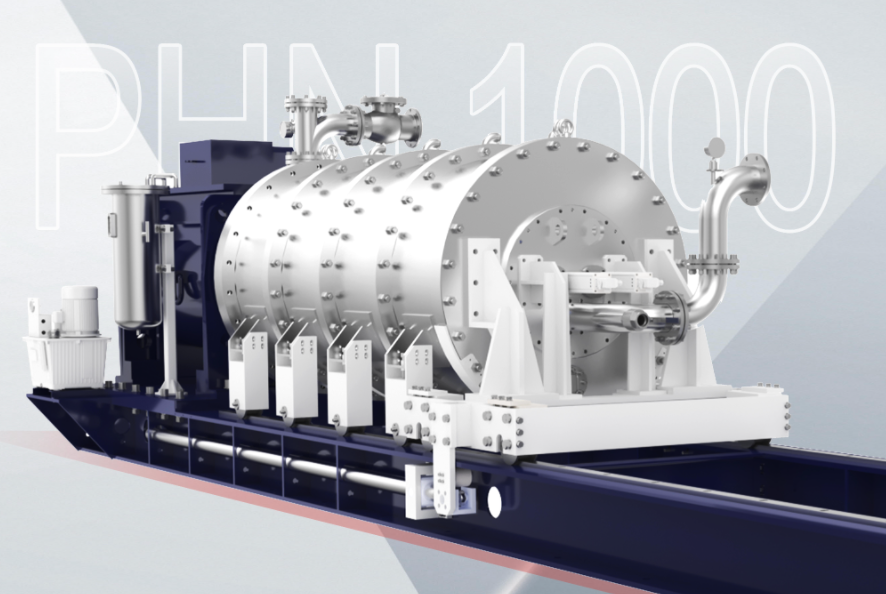

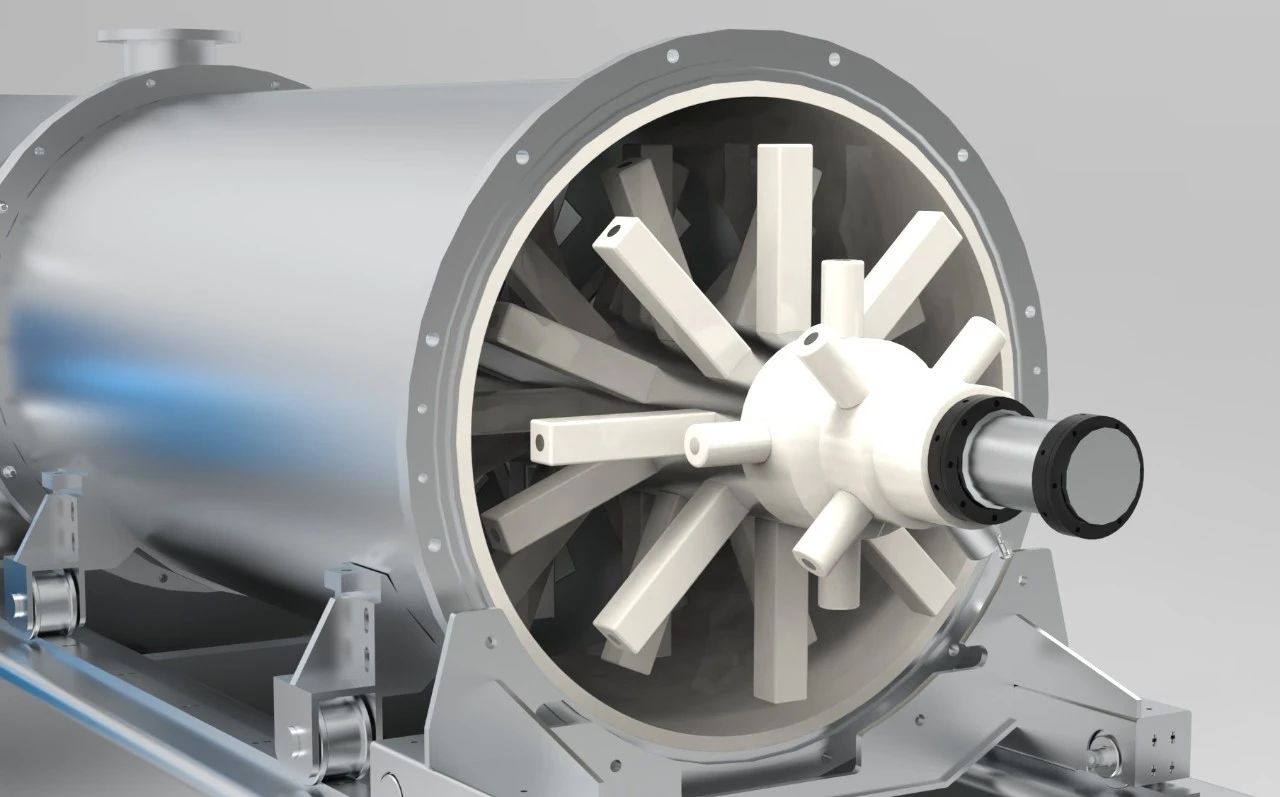

The PUHLER Nanomill is equipped with three core technologies:

The PUHLER PN series of nanomills and the DHM series of dry grinding mills adopt a rod pin structure combined with a multi-stage grinding chamber design, ensuring that the D90 deviation of the material is less than 5%, with batch consistency reaching an internationally leading level.

With full ceramic lining (zirconia/silicon carbide) and a full ceramic rotor, the mill ensures that the metal impurity leaching is less than 10ppm, meeting the stringent purity requirements for solid electrolytes.

03 Intelligent Process Closed Loop

The mill features built-in online particle size monitoring (using laser diffraction technology) and intelligent real-time parameter adjustment, which increases grinding efficiency by 40% and reduces energy consumption by 30%.02

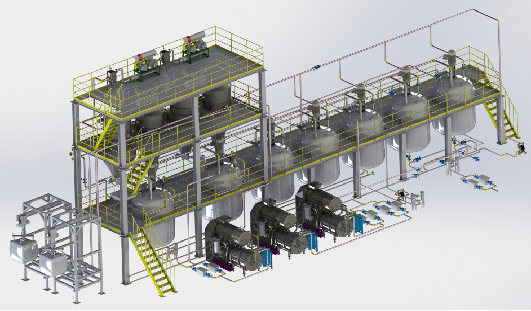

Full-Chain Coverage in Material Preparation

For the oxidation-sensitive nature of sulfides (such as Li₃PS₄), a customized inert gas protection system is provided with an oxygen content of less than 0.1ppm.

Achieving a single-pass grinding of NCM811 to D50 = 150nm with a specific surface area greater than 15m²/g, which helps enhance interfacial stability.

By designing a shear-impact composite force field, the problem of silicon particle agglomeration is solved, reducing the expansion rate to within 120%.

03

EPC Engineering Digital Solutions

PUHLER's EPC engineering digital solutions cover every aspect of power battery production, enhancing the traceability of product quality and facilitating the analysis of production data. This provides a basis for optimizing processes and increasing production capacity, ensuring the stability and efficiency of the production line.

Conclusion