On February 17, 2025, the General Secretary presided over a symposium for private enterprises, once again clarifying the direction for the development of the private economy and injecting strong confidence. At the symposium, the General Secretary emphasized that the private economy has a broad prospect and great potential for development, and that it is the right time for private enterprises and entrepreneurs to fully demonstrate their capabilities. This has given our private enterprises a powerful boost and allowed us to see an even brighter future.

It is worth noting that, in terms of the invited enterprises, private entrepreneurs in the technology sector became the core of this symposium, covering cutting-edge fields such as artificial intelligence, intelligent manufacturing, semiconductors, and new energy. These areas represent the development direction of new-quality productive forces and reflect the new trends in China's economic development. They also signal the arrival of a new golden age for the private economy.

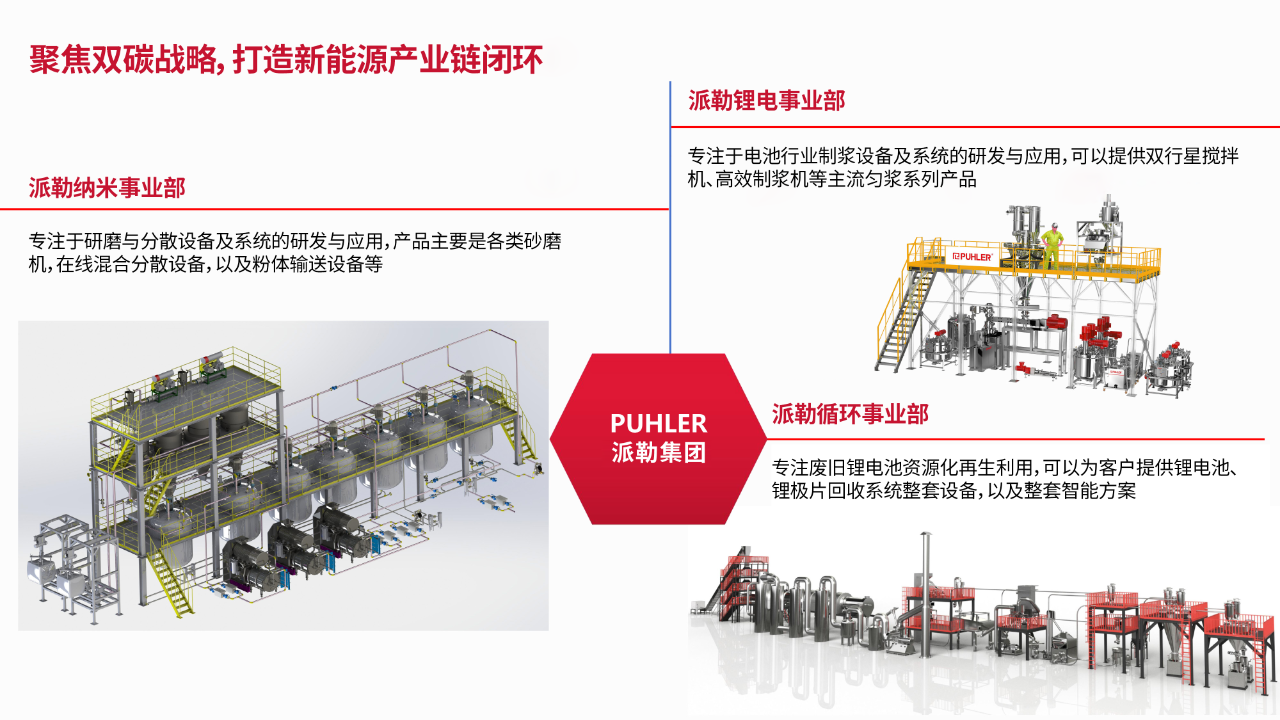

Since its establishment, the PUHLER Group has profoundly recognized that only by closely following the national strategy can it find the right direction in fierce market competition and achieve sustainable development. Against the backdrop of the new era, the PUHLER Group, with its keen foresight and outstanding innovation capabilities, has actively laid out in several key areas and achieved resonance with the development of industries under the new-quality productive forces.

Diversified Business Layout

Deep Integration into National Strategic Industrial Chains

As a national-level "little giant" enterprise specializing in the research and development, manufacturing, sales, and service of micro-nano grinding and polishing equipment, as well as integrated multi-axis CNC systems, and a national high-tech enterprise, the PUHLER Group owns four major industrial companies: Guangdong Puhler Intelligent Nanotechnology Co., Ltd., Hunan Jinling Machine Tool Technology Group Co., Ltd., Hermann Precision Machine Tool (Guangdong) Co., Ltd., and Changsha Jinling Software Technology Co., Ltd. These four companies, like the four horses of the group, work together in different fields to drive the group's development.

Technology Innovation Drives Development and

Breakthroughs in Key Core Technologies

Technological innovation has always been the core driving force behind the development of the PUHLER Group. In the field of micro-nano grinding processes, we have continuously broken through technological bottlenecks, becoming one of the few domestic enterprises capable of manufacturing grinders with a capacity of 5,000 liters and a fineness of 50 nanometers.

We are also the first domestic enterprise to mass-produce and stably supply 50nm grinders. In the field of lithium battery slurry preparation, our "TWIN SHIFT" series of topological helical twin-rotor intelligent slurry preparation systems have achieved the domestication of fully automated lithium battery manufacturing equipment technology and have even surpassed the performance of imported products. In the field of power battery recycling, our independently developed integrated process technology and equipment for recycling waste batteries—featuring "electrified crushing, low-temperature pyrolysis, coupled separation, and material regeneration"—represent a significant innovation in domestic and international waste lithium-ion battery recycling equipment technology and are at the international leading level.

In the field of CNC machine tools and CNC systems, our independently developed HGC and HUC series of high-end five-axis machining centers have achieved comprehensive domestication from machine design, machining accuracy, to key components and control systems, with an autonomy and controllability rate exceeding 85%. The DELTA WHM 632i Ultra V2 five-axis machining center CNC system has made a significant breakthrough in sub-nanometer precision motion control, endowing China's high-end equipment with a domestic "smart brain."

These technological innovation achievements not only give us a competitive edge in the market but also successfully break through the technological blockade from the West, effectively solving the "bottleneck" problems of domestic high-end equipment. They have laid a solid foundation for our industrial upgrading and sustainable development.

Our products and technologies have also gained widespread recognition internationally. These market achievements not only reflect our market competitiveness but also demonstrate the rationality and foresight of our industrial layout.