Recently, two HGC650W five-axis linkage vertical machining centers of Hermann Precision Machinery successfully completed the loading process and officially set off for Shaanxi, marking a new leap in the technical strength and market share of Jinling Machine tools in the field of high-end machine tool manufacturing.

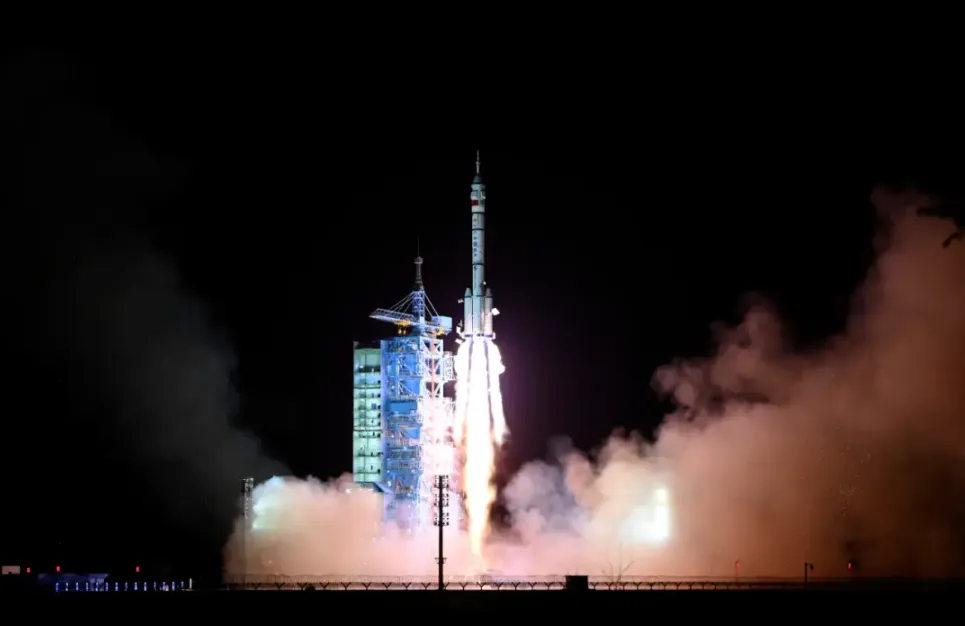

Aerospace field

The journey begins

As an important birthplace of China's space power, Shaanxi has a strong aerospace industry foundation, and recently released the "Shaanxi Province to cultivate 100 billion commercial space industry innovation Cluster Action Plan", aimed at accelerating the cultivation of 100 billion commercial space industry innovation cluster, to create a global influence of the commercial space industry innovation development highland. In this context, Hermann precision machine successfully landed in Shaanxi, which undoubtedly marks another solid and important step on the journey of Jinling Machine tool in the aerospace field.

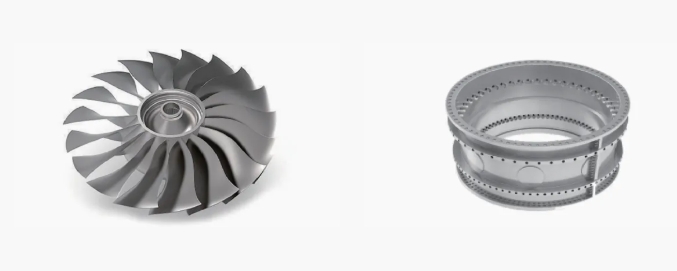

As we all know, the parts of the aerospace industry usually have highly complex surface geometric characteristics, and the processing accuracy requirements are extremely strict, traditional ordinary machine tools have been unable to adapt to this market demand. With its advanced control system and precision multi-axis linkage mechanism, the five-axis machining center shows excellent complex surface processing capabilities, and can precisely manufacture high-precision and difficult key components such as aircraft leaf discs and aircraft engines, which is highly in line with the needs of industrial development.

In recent years, with the rapid advancement of domestic five-axis machining center manufacturing technology, a number of leading domestic machine tool brands are gradually narrowing the gap with top international brands. This positive change has led to a shift in the market landscape, which has long been dominated by foreign brands. More and more domestic five-axis machining centers, with their outstanding performance, have successfully entered the aerospace field, injecting strong technical momentum and equipment support into the vigorous development of China's aerospace industry. Hermann Precision Machinery is one of the outstanding representatives in this regard.

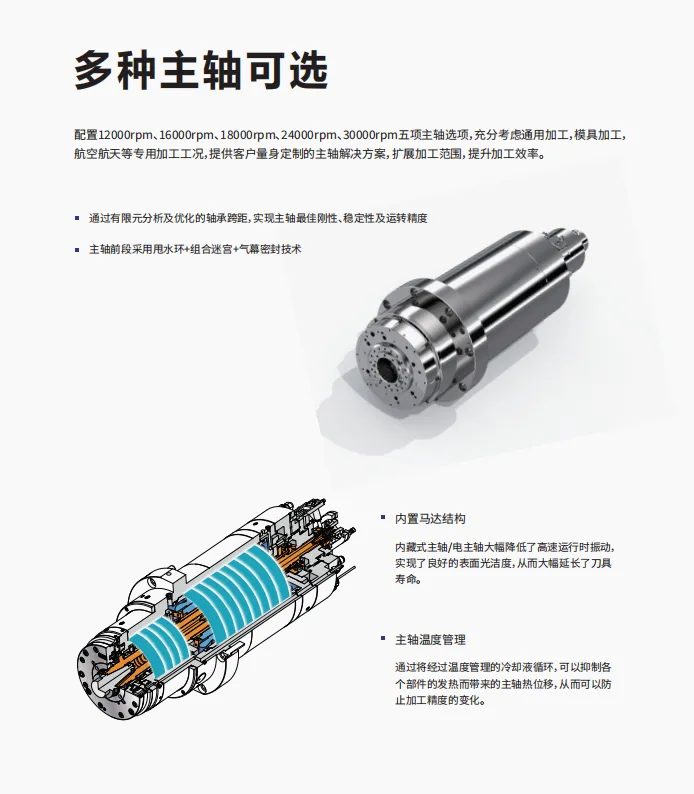

The HGC650W five-axis linkage vertical machining center, developed by Hermann Precision Machinery, is a masterpiece designed to meet the urgent demand for five-axis simultaneous machining technology in high-end manufacturing fields such as aerospace, military, molds, and new energy vehicles. This equipment integrates advanced bed structure design concepts, ensuring the stability and precision of the machine tool during high-speed operation through precise analysis and optimization, providing a solid guarantee for the precision machining of complex parts.

The HGC650W five-axis linkage vertical machining center, developed by Hermann Precision Machinery, is designed to meet the high-performance and high-precision processing demands of the aerospace industry. It allows customers to flexibly choose and configure high-performance spindles and A/C axis cradle rotary tables according to specific processing needs. This enables high-speed, efficient, and high-precision machining of various complex curved parts. The positioning accuracy and repeat positioning accuracy reach the micron level, meeting the stringent requirements of the aerospace field for difficult-to-process materials and complex structures. This provides strong technical support and productivity assurance for customers' factories.

Looking to the future, Hermann Precision Machinery will continue to focus on the high-end five-axis vertical machining center field, constantly optimizing product structures and enhancing service quality. They are committed to overcoming technical challenges in order to provide customers with more efficient, intelligent, and sustainable manufacturing solutions. This will not only support the advancement of China's aerospace industry to higher levels but also help to create a more brilliant chapter of development.